TECHSPEC® 부품은 에드몬드 옵틱스가 설계, 사양 지정 및 제조하는 제품입니다. 더 알아보기

TECHSPEC® 부품은 에드몬드 옵틱스가 설계, 사양 지정 및 제조하는 제품입니다. 더 알아보기

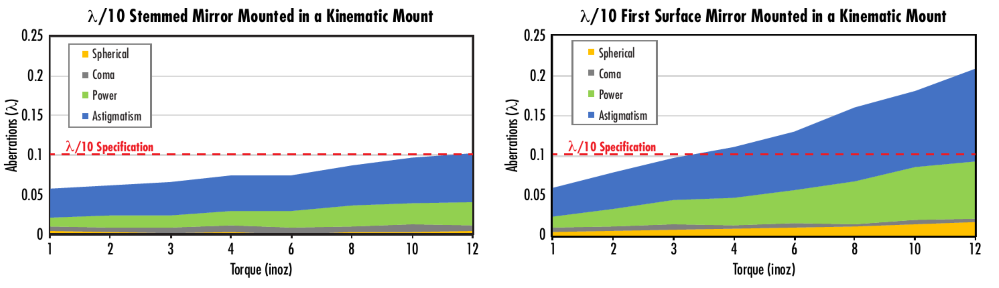

TECHSPEC® Metallic Coated Stemmed Mirrors는 강화 및 보호 금속 코팅 처리된 미러에 낮은 장착 응력을 제공합니다. TECHSPEC® Kinematic Circular Optical Mounts 및 E-Series Kinematic Optical Mirror Mounts에 장착되도록 설계된 이 미러는 미러와 키네마틱 마운트 간의 모든 접촉은 스템으로 조절됨에 따라 미러 표면에 가해지는 응력이 줄어듭니다. 또한 응력 감소 디자인와 모놀리식 용융 실리카 구조를 채택하여 기존의 mounted λ/10 first surface mirror에 비해 열안정성이 뛰어나고 향상된 표면 평탄도와 내구성을 제공합니다. TECHSPEC® Metallic Coated Stemmed Mirrors는 광학 시스템에 장착 및 결합이 용이해 VIS 및 IR 스펙트럼에서 빔을 조정하거나 반사시키는 용도에 이상적으로 사용할 수 있습니다.

참고: 맞춤형 옵션은 당사로 문의 바랍니다.

에드몬드옵틱스는 특정 어플리케이션 요건을 충족할 수 있는 광학 및 이미징 부품에 대한 포괄적인 맞춤형 제조 서비스를 제공합니다. 에드몬드옵틱스는 프로토타입 개발, 본격적인 생산 준비 단계 등 단계와 관계없이 고객의 니즈를 충족하는 유연한 솔루션을 제공합니다. 에드몬드옵틱스의 엔지니어는 전 개발 과정을 지원합니다.

에드몬드옵틱스의 제조 역량:

자세한 내용은 에드몬드옵틱스의 맞춤형 제조 역량 페이지를 확인하거나 여기로 문의 바랍니다.

본사 및 지사별 연락처 확인하기

견적 요청 도구

재고 번호 입력 필요

Copyright 2023, 에드몬드옵틱스코리아 사업자 등록번호: 110-81-74657 | 대표이사: 앙텍하우 | 통신판매업 신고번호: 제 2022-서울마포-0965호, 서울특별시 마포구 월드컵북로 21, 7층 (서교동, 풍성빌딩)

The FUTURE Depends On Optics®