TECHSPEC® 부품은 에드몬드 옵틱스가 설계, 사양 지정 및 제조하는 제품입니다. 더 알아보기

TECHSPEC® 부품은 에드몬드 옵틱스가 설계, 사양 지정 및 제조하는 제품입니다. 더 알아보기

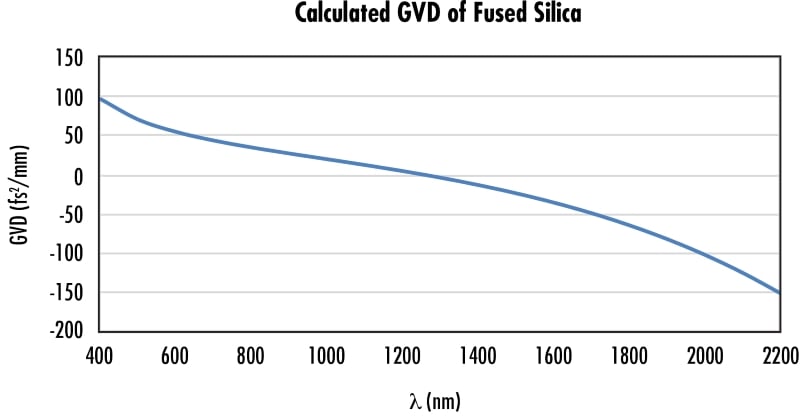

TECHSPEC® Ultrafast Thin Windows는 군지연분산(GDD)을 제한하기 위해 1mm 두께로 설계되어 극초단 레이저 용도에 사용하기 적합합니다. 두께가 매우 얇은 이 윈도우는 370nm - 2.2μm의 파장 범위에서 낮은 반사율을 제공하도록 최적화된 ion-beam sputtered (IBS) 광대역 AR 코팅을 양면에 적용할 수 있습니다. IBS 코팅 프로세스는 또한 기존의 AR 코팅 윈도우보다 흡수 손실 및 산란을 감소시켜 줍니다. TECHSPEC® Ultrafast Thin Windows는 소형의 고성능 광학 윈도우가 필요한 일반 광학 용도에서도 사용이 가능합니다. Uncoated Thin Window substrates(UV Fused Silica 또는 IR Grade Fused Silica)는 고객의 어플리케이션의 요건을 충족하기 위해 맞춤 코팅 옵션을 적용할 수 있으며 기타 자세한 사항은 당사로 문의 바랍니다.

IR grade fused silica는 OH-이온의 양이 감소하여 UV grade fused silica와 차이가 있으므로 NIR 스펙트럼 영역에서 더 높은 투과율을 제공하고 UV 스펙트럼에서는 낮은 투과율을 제공합니다.

1-800-363-1992

본사 및 지사별 연락처 확인하기

견적 요청 도구

재고 번호 입력 필요

Copyright 2025, 에드몬드옵틱스코리아 사업자 등록번호: 110-81-74657 | 대표이사: 앙텍하우 | 통신판매업 신고번호: 제 2022-서울마포-0965호, 서울특별시 마포구 월드컵북로 21, 7층 (서교동, 풍성빌딩)