TECHSPEC® 부품은 에드몬드 옵틱스가 설계, 사양 지정 및 제조하는 제품입니다. 더 알아보기

TECHSPEC® 부품은 에드몬드 옵틱스가 설계, 사양 지정 및 제조하는 제품입니다. 더 알아보기

| 가격(부가세 별도/Tax excluded) | |

|---|---|

| 수량 1-5 | KRW 515,309 개당 |

| 수량 6-25 | KRW 412,206 개당 |

| 수량 26-49 | KRW 386,868 개당 |

| 더 필요하신가요? | 견적 요청 |

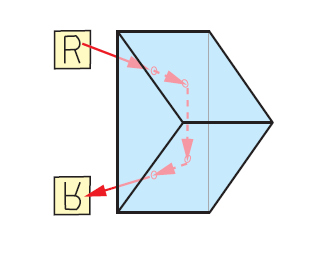

TECHSPEC® Nd:YAG Laser Line λ/20 UV Fused Silica Right Angle Prism은 정밀한 표면 평탄도에 보증받은 laser damage threshold AR 코팅이 접목된 제품입니다. 이 프리즘은 모든 표면의 평탄도가 λ/20이기 때문에 웨이브프런트 왜곡을 최소화하면서 빔을 조정하는 용도에 이상적으로 사용할 수 있습니다. ±15 arcsecond의 각도 허용 오차로 대량 통합 용도에서 일관된 정렬이 보장됩니다. TECHSPEC® Nd:YAG Laser Line λ/20 UV Fused Silica Right Angle Prism은 무반사 코팅 처리가 된 프리즘의 레그(leg)를 통해 투과가 일어나도록 설계되었습니다. 수직적 통합 제작 공정으로 맞춤 제작 요청에 따라 손쉽게 사이즈를 조정할 수 있습니다.

에드몬드옵틱스는 특정 어플리케이션 요건을 충족할 수 있는 광학 및 이미징 부품에 대한 포괄적인 맞춤형 제조 서비스를 제공합니다. 에드몬드옵틱스는 프로토타입 개발, 본격적인 생산 준비 단계 등 단계와 관계없이 고객의 니즈를 충족하는 유연한 솔루션을 제공합니다. 에드몬드옵틱스의 엔지니어는 전 개발 과정을 지원합니다.

에드몬드옵틱스의 제조 역량:

자세한 내용은 에드몬드옵틱스의 맞춤형 제조 역량 페이지를 확인하거나 여기로 문의 바랍니다.

본사 및 지사별 연락처 확인하기

견적 요청 도구

재고 번호 입력 필요

Copyright 2023, 에드몬드옵틱스코리아 사업자 등록번호: 110-81-74657 | 대표이사: 앙텍하우 | 통신판매업 신고번호: 제 2022-서울마포-0965호, 서울특별시 마포구 월드컵북로 21, 7층 (서교동, 풍성빌딩)

The FUTURE Depends On Optics®